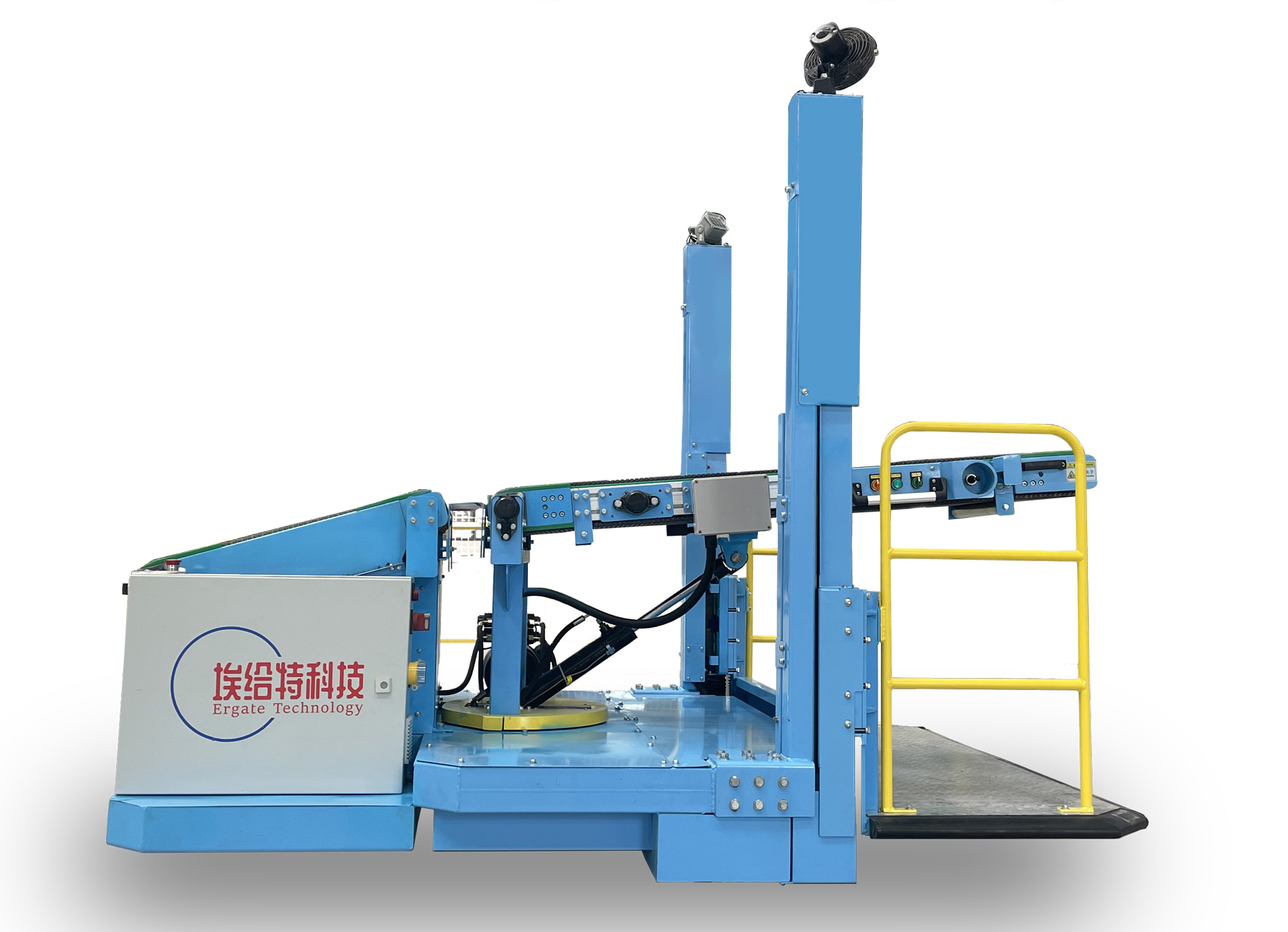

ERG Container Loading & Unloading Conveyor Compact Version

Used for cross-border E-commerce overseas warehouses with a large number of SKU.

- Ergonomic design to reduce loading or unloading intensity.

Product Name: ERG Container Loading & Unloading Conveyor Compact Version

Detailed Description:

- Basic parameters:

| Parameter Table of ERG Container Loading and Unloading Conveyor Compact Version | |||

| Size of Package | L2450*W1800*H2200mm | Net Weight | 1300-1600kgs |

| Working Voltage | 110-240V | Operation Voltage | 24V |

| AGV Power Supply | Rechargeable battery DC 48V50AH (Buy it locally) | Package Weight | 50kgs/pc maximum |

| Total Power | 3kw Maximum | Push Rod | Hydraulic |

| Conveying Option | Loading and Unloading | Conveying Speed | 15-30m/min ( adjustable ) |

| Application | 20’/40’ GP container or 40’ HQ container | Conveying medium | Belt or Chain Plate |

| Vehicle loading ramp | 15° maximum | Efficiency | 600-2500pcs/hour maximum |

2. Application:

2.1 Cross-border E-commerce warehouses

2.2 Bagged granule or powder handling

2.3 Automobile tire handling

2.4 Office furniture handling

2.5 Sanitary ware handling

2.6 Home appliance handling

2.7 Cold chain warehousing

3. Features:

— Ergonomic design helps the operator get much closer to the packages to be unloaded in a container or truck, as the ERG conveyor could move easily forward or backward, left or right. Meanwhile, the operation panel and platform could rise or descend together or separately according to actual need. Moreover, the operation panel could swing left or right to reach the packages at two far sides.

— Deft travel: ERG Container Loading and Unloading Conveyor could travel interhouse or between docks with its own rechargeable battery. It is another prominent advantage to other telescopic or truck loading conveyors. It will also improve the working efficiency and reduce total investment in the loading or unloading equipment.

Operation & Maintenance Manual of ERG Container Loading and Unloading Conveyor v02-ENG

More options:

—— We are mainly committed to providing comprehensive solutions for cross-border e-commerce overseas warehouses at home and abroad. While fully realizing ergonomic loading and unloading, we can also use DWS system to collect SKU information and accordingly with the warehouse management system to achieve communication and data exchange. We use mechanical arms or robots for efficient stacking, and AGV to transport to designated shelves or piles.

—– We will provide cost-effective overall solution, the most reliable products, the best services, and the most stable system for domestic and foreign cross-border E-commerce overseas warehouses.

——- finish line